Last Updated on January 22, 2026 by Admin

Table of Contents

- What is Food Hygiene?

- What is Food Safety?

- Examples of Food Safety Systems

- Best Manufacturing Practices To Maintain Good Food Hygiene

- The Importance of Personal Hygiene for Food Handlers

- Benefits of Practicing Food Manufacturing Hygiene

- Cons of Not Maintaining Food Manufacturing Hygiene

- Why It’s Important to Train for Food Hygiene

- Conclusion

- Frequently Asked Questions

Every human being needs food to survive. Its preparation, processing, and packaging entail a massive responsibility on manufacturers to ensure it’s safe for consumption. It necessitates strict hygiene standards in food manufacturing. This article dives deep into the nitty-gritty of food hygiene and safety. It provides guidelines to ensure impeccable hygiene standards in food manufacturing.

What is Food Hygiene?

Food hygiene in food industry refers to the practices and conditions necessary to control foodborne illnesses and ensure food produced for consumption is safe and won’t lead to health hazards. It encompasses everything from how the food is stored, handled, and prepared, and even how it’s consumed.

Examples of Food Hygiene Practices

Food hygiene practices include washing hands before handling food, sanitizing equipment and surfaces, wearing clean uniforms, and using gloves or hairnets. Regular cleaning of kitchen areas, proper waste disposal, safe food storage at correct temperatures, and preventing cross-contamination are essential. These practices help reduce the risk of foodborne illnesses and maintain overall food safety standards.

What is Food Safety?

Food safety is a broader term encompassing all the measures and techniques to ensure food is free from harmful chemical, physical, or biological substances. It involves setting standards for pesticide residues, additives, and veterinary drugs. It also covers good manufacturing practices, guidelines on packaging, labelling, and proper storage.

Examples of Food Safety Systems

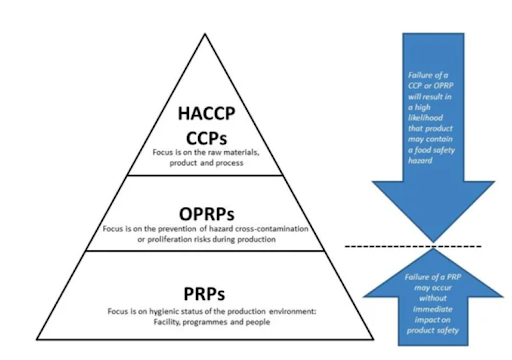

Food-safety systems are sensible plans that guide workers in keeping food clean from start to finish. A well-known example is HACCP, which spots dangers and sets up crucial checkpoints before food leaves the plant. ISO 22000 blends that safety approach with wider quality rules so firms manage both at once. Good Manufacturing Practices, or GMP, lay down basic rules for hygiene, equipment, and worker habits. In India, FSSAI issues broad regulations that help processors and restaurants meet safe-food goals. From a global perspective, Safe Quality Food (SQF) and BRCGS standards are popular with brands that export products. Altogether, these frameworks build trust with shoppers, keep companies in line legally, and boost the bottom line.

Best Manufacturing Practices To Maintain Good Food Hygiene

Cleanliness

A steady cleaning plan helps keep small issues from spreading across the production space. Workers should follow simple steps to remove waste before it builds up and affects daily output.

Efficient Facility Layout

A smart layout supports safe movement of workers and materials without long delays. Clear space between stations keeps traffic smooth and reduces mistakes that may happen during busy hours.

Storage

Each storage zone should be labeled so staff can find items fast and avoid confusion. Regular checks help confirm that goods stay within safe limits during long production cycles.

Separation

Different stages of food handling should stay apart to lower the chance of mixing items that should not touch. Simple barriers and clear signs help workers follow the right path every time.

Prevention of Cross- Contamination

Ensure that raw and cooked foods are separated to prevent cross-contamination.

Temperature Control

Monitor and maintain proper temperatures for storing, cooking, and serving food.

Pest Control

Putting consistent pest control in place keeps food processing zones clean and stops cross-contamination. Routine checks, sealing gaps, and using safe-approved products block unwanted insects and rodents. Following these steps protects product quality, lowers health hazards, and meets industry safety rules.

Regular Audits

Carry out routine hygiene and safety checks to keep standards strong. Frequent in-house reviews paired with outside inspections spot risks early, meet food-safety rules, and win customer confidence by being open and answerable.

The Importance of Personal Hygiene for Food Handlers

The individual involved in food production can be a source of contamination if they don’t maintain personal hygiene. Here’s why it’s paramount:

1. Disease Carriers: Food handlers can introduce pathogens to food if they are ill or carry bacteria.

2. Physical Contaminants: Hair, jewellery, or other personal items can get into food if precautions are not taken.

3. Cross-contamination: Improper hand washing can transfer pathogens from one food item to another.

For these reasons, training on personal hygiene, regular health check-ups, and proper attire (like hairnets and gloves) are essential for food handlers.

Also Read: Food Safety and Hygiene: Your Burning Questions Answered

Benefits of Practicing Food Manufacturing Hygiene

The benefits of practising and maintaining hygiene in food manufacturing go beyond just producing safe food.

Consumer Safety

One of the primary responsibilities of any food manufacturer is to guarantee the health and safety of the end consumer. Strict hygiene practices help curb the spread of pathogens and contaminants that can cause foodborne illnesses. Such practices not only ensure that the food product is safe but also that it maintains its quality and nutritional value.

Brand Reputation

In the digital age, where news travels fast, one mishap can significantly tarnish a brand’s reputation. Conversely, consistently adhering to high hygiene standards becomes a badge of honour, bolstering consumer trust.

Regulatory Compliance

Different countries have stringent food safety and hygiene standards set by governmental bodies. By adhering to these standards, manufacturers avoid potential legal repercussions, including penalties and shutdowns. It also becomes easier for them to get certifications, further boosting their market credibility.

Reduced Wastage

Good hygiene practices often go hand-in-hand with proper storage and handling procedures. It minimises the risk of spoilage, contamination, and wastage, leading to optimised production costs and sustainability in operations.

Lowered Risk of Litigation

Keeping the chance of lawsuits low lets a company guard its good name and sidestep expensive courtroom fights. When firms follow labor rules, safety guidelines, and plain good ethics, they build a workplace where workers quarrel less, regulators complain less, and the business can run smoothly over the years.

Job Security for Employees

Knowing their jobs are safe gives workers peace of mind and forms a solid base for a smooth, productive office. That sense of safety fuels loyalty, cuts down on people leaving, and lifts spirits across the team. When staff truly believe their roles are secure, they work harder, pitch fresh ideas, and back the company’s long-term goals.

Increased Profitability

A robust hygiene system can have a ripple effect. With reduced wastage, no regulatory fines, and increased consumer trust, manufacturers can see a direct impact on their profitability. Happy consumers often translate to repeat purchases and referrals, further enhancing the business’s bottom line.

Cons of Not Maintaining Food Manufacturing Hygiene

Neglecting hygiene in food manufacturing is a dangerous oversight, leading to grave consequences for consumers and manufacturers.

Health Risks

At the forefront is the risk posed to consumers. Contaminated food can lead to many health issues, from minor allergies to severe foodborne diseases and even death in extreme cases.

Financial Losses

A single recall can have significant financial implications. Apart from the immediate costs associated with the memory, subsequent legal actions from affected consumers could lead to compensations and damages.

Brand Damage

With the ease of access to information, consumers are more aware than ever. Adverse publicity or news of contamination can erode trust, causing long-term damage to the brand’s image and reducing its market share.

Regulatory Penalties

Failure to comply with hygiene standards can lead to regulatory actions. These can range from hefty fines and temporary shutdowns to complete licence revocations in severe cases.

Read Also – A Food Handler Guide to Personal Hygiene

Why It’s Important to Train for Food Hygiene

Understanding food hygiene’s significance is only half the battle; ensuring its practical implementation is equally crucial.

Knowledge Transfer

Training provides food handlers and manufacturers with up-to-date knowledge of potential hazards, from contaminants to allergens.

Skill Development

Beyond just theoretical knowledge, training imparts practical skills. Whether it’s the correct method to sanitise equipment or the appropriate way to store perishables, these skills become second nature with proper training.

Cultural Integration

When a team undergoes training, it fosters a safety culture. Everyone becomes accountable, and hygiene standards become a daily routine rather than an imposed regulation.

Meeting Regulatory Standards

Many regulatory bodies mandate periodic training as part of their compliance checklist. Hence, regular training sessions ensure that manufacturers remain compliant and updated.

Moral Responsibility

At its core, ensuring food hygiene is about valuing human life and health. Training reinforces this moral responsibility, ensuring that every individual in the food production chain understands the impact of their actions on end consumers.

Conclusion

Everyone in the food industry ensures the utmost food hygiene and safety standards. Proper training, adherence to guidelines, and an unwavering commitment to consumer health can lead to a win-win situation: safe food for consumers and sustained profitability for manufacturers.