Last Updated on May 21, 2025 by Admin

Table of Content

- Origin/ History of 5S principles

- What are the 5S Principles?

- Methododlogy Of Implementing 5s In Food Industry

- Importance of 5S in the Food Industry

- Types of 5S

- Advantages of 5S Implementation in the Food Industry

- Conclusion

Maintaining efficiency, cleanliness, and safety are paramount in a fast-paced and demanding industry like food production. Have you ever contemplated what goes behind ensuring safe food to the consumers? One such highly effective approach that has revolutionised the food industry is the implementation of 5S in the food industry. By focusing on organisation, cleanliness, and standardised work practices, 5S has become a cornerstone of excellence for food manufacturers. This article will delve into what are the 5S principles, their importance, their different types, and how it enhances food safety.

Origin/ History of 5S principles

- Formerly known as- ‘Toyota Production System’

- Developed by Taiichi Ohno and Eiji Toyoda with Japanese industrial engineers in 1950

- Improvised by Sakichi Toyoda (Father of the Japanese industrial revolution), his son Kiichiro and Taiichi Ohno redesigned “TPS” and named as “5S”.

- About first company that implemented 5S, what were the results/affects

What are the 5S Principles?

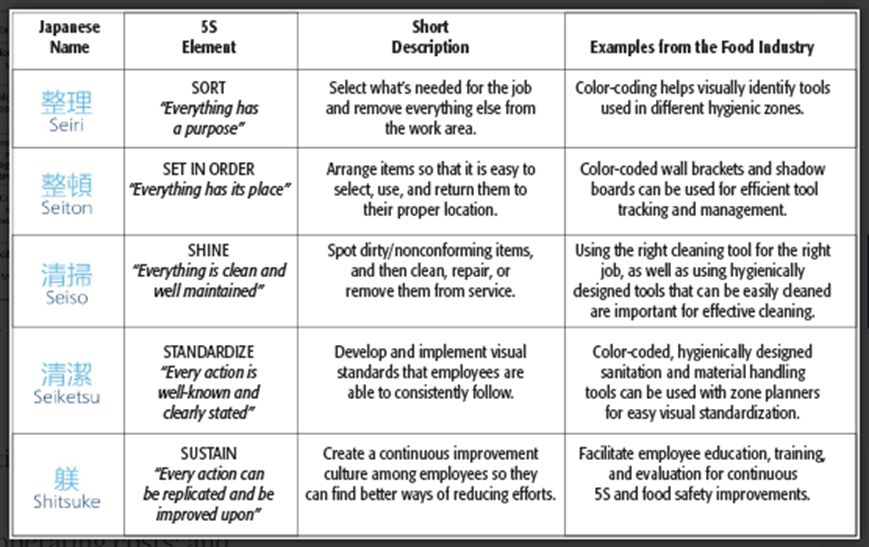

The 5S principles originated in Japan and formed the foundation of Lean Management. The acronym “5S” comes from a combination of five Japanese words: Seiri (which means “sort”), Seiton (which means “set in order”), Seiso (which means “shine”), Seiketsu (which means “standardise”), and Shitsuke (which means “sustain”). Each principle emphasises specific actions to create a well-organised and efficient workplace.

- Sort (Seiri): This step involves sorting through all items in the workspace and keeping only what is necessary for daily operations. Unnecessary items are removed to create a clutter-free environment.

- Set in Order (Seiton): In this phase, items that remain after sorting are organised and arranged systematically. Everything should have its specific location, making it much simpler for workers to look for and obtain the goods and tools they need.

- Shine (Seiso): This principle’s main objectives are cleaning and maintaining a clean workplace. Regular cleaning routines are established to eliminate dirt, dust, and potential contaminants.

- Standardise (Seiketsu): Standardising work practices and procedures ensure consistency and efficiency. Visual aids like colour-coded labels and floor markings maintain an organised environment.

- Sustain (Shitsuke): The final principle focuses on creating a culture of continuous improvement and self-discipline. All employees are actively involved in maintaining the 5S practices.

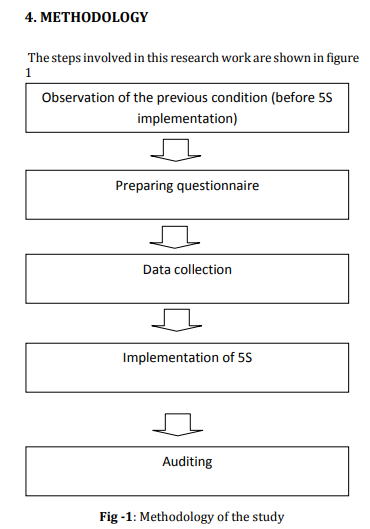

Methododlogy Of Implementing 5s In Food Industry

Importance of 5S in the Food Industry

The implementation of 5S principles in the food industry yields numerous benefits:

- Enhanced Efficiency: 5S implementation ensures safety in the food industry by creating a streamlined workflow, reducing time wasted searching for tools or equipment. This efficiency results in increased productivity and reduces operational costs.

- Improved Safety: A well-organised and clean workspace minimises the risk of accidents and injuries. It also ensures that safety protocols are followed diligently.

- Quality Control: With 5S practices, standardisation becomes the norm. It leads to consistent production processes, resulting in products of higher quality.

- Waste Reduction: By eliminating unnecessary items and organising resources, 5S reduces waste generation and optimises resource utilisation.

- Employee Engagement: Involving employees in the 5S implementation fosters a sense of ownership and pride in the workplace, boosting morale and job satisfaction.

Types of 5S

While the core principles of 5S remain the same, different industries may adapt the methodology to suit their specific needs. In the food industry, two common types of 5S are:

- 6S: Some food manufacturers include “Safety” as the sixth S. Safety measures, such as proper handling of hazardous materials and personal protective equipment, are integrated into the 5S practices.

- 5S+1T: This variation adds “Training” as the sixth element. It emphasises the importance of continuous training and skill development to ensure employees can maintain the 5S practices effectively.

Advantages of 5S Implementation in the Food Industry

One of the most significant advantages of 5S implementation in the food industry is its positive impact on ensuring safety in the food industry. By following 5S in the food industry, potential hazards and risks are significantly reduced, leading to safer food production and handling.

Organised Storage: Proper storage practices, such as raw and ready-to-eat foods separately, are essential to prevent cross-contamination. The “Set in Order” principle ensures that storage areas are marked, reducing the risk of mixing different food items.

Regular Cleaning: The “Shine” principle emphasises regular cleaning of workspaces and equipment. It reduces the build-up of food residues and potential allergens, promoting a hygienic environment.

Standardised Procedures: As emphasised in the “Standardise” principle, standardising processes ensure that all employees follow uniform protocols. This consistency minimises errors and variations in food handling, reducing the chances of contamination.

Read Also: 7 principles of HACCP – Detailed guidance

Conclusion

5S principles have proven to be a powerful tool in maximising the food industry’s efficiency, cleanliness, and safety. By implementing Sort, Set in Order, Shine, Standardize, and Sustain practices, food manufacturers can achieve organised workspaces, reduced waste, improved quality, and, most importantly, enhanced food safety. 5S and food safety go hand in hand.

It is a holistic approach involving all employees and creating a continuous improvement culture. Adopting 5S in the food industry sets the stage for success in a competitive and safety-conscious sector, whether a small-scale food business or a large food production facility. Embrace the 5S philosophy, and witness your food business flourish with heightened efficiency, improved quality, and a safer work environment.