- About

- Qualifications

- Training Assessments & Certification

- Training Network

- Digital Resources

- Media

- Empanel with FICSI

- Job Portal

- Contact

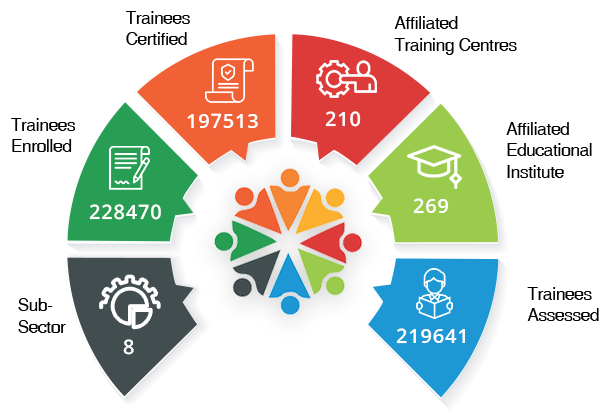

Food Industry Capacity & Skill Initiative (FICSI) offers skilling programs leading to certification, placement , capacity building and entrepreneurship focusing on the Food Processing Industry.

FICSI has created a vibrant ecosystem that includes standards, model curriculum and learning resources, a network of affiliated training centres and Vocational Colleges, supported by industry experts master trainers and assessors for providing industry relevant skills. The National Council for Vocational Education & Training (a regulatory body under the Union Ministry of Skill Development and Entrepreneurship) has recognised FICSI as an awarding body.

Read More

“FICSI’s Food Processing Skills Training is not limited to creating entrepreneurs and talent for the industry but also for addressing macro issues like unlocking the true value of Indian agricultural output, sustainability, women empowerment, health, nutrition and food security.”

Food Industry Capacity & Skill Initiative (FICSI)—widely known as Food Processing Sector Skill Council—is a Not-for-Profit Organization, registered under the Societies Registration Act, 1860 and working under the aegis of Ministry of Skill Development and Entrepreneurship. The organization is Promoted by the Federation of Indian ...

National Occupational Standards (NOS) describe best practices by bringing together performance criteria, knowledge and skills pertaining to a job role. A set of NOSs related to a specific job role is called Qualification Pack (QP). Each NOS defines one key function in a job role.

Food Industry Capacity & Skill Initiative (FICSI)—widely known as Food Processing Sector Skill Council—is a Not-for-Profit Organization, registered under the Societies Registration Act, 1860 and working under the aegis of Ministry of Skill Development and Entrepreneurship. The organization is Promoted by the Federation of Indian ...

Bachelor of Vocation (B.Voc) in Food processing is a three year program focused on universities and colleges providing undergraduate studies covering Skill Component (Job roles) and General Education component.

FICSI was set up as a one of its kind, Public PrivatePartnership Organisation by National Skill Development Corporation with the primary mandate of catalysing the skills landscape in India. FICSI invites proposals from interested entities for affiliation as a Vocational training Provider in Food Processing Job Roles.

FICSI offers online courses for food professionals and students looking for upskilling in the food sector. Our Learning Management System makes it easy for you to learn and get certified to work in the food industry. The platform is specially designed for training individuals and organizations from the food industry.

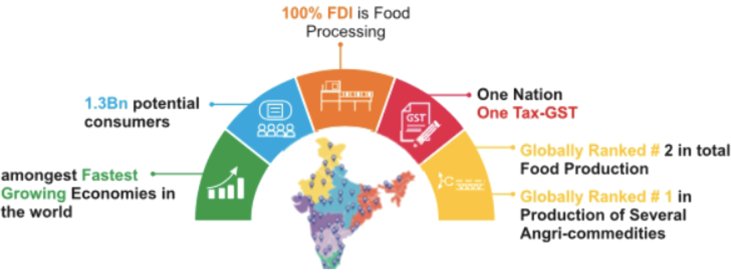

Food Processing sector has huge opportunity in entrepreneurship with optimum capital investment. According to Ministry of Food Processing Industries, food processing is employment intensive in that for every Rs. 1 million invested, 1.8 jobs and 6.4 indirect jobs are created.

The food industry in India is growing at an exponential pace in terms of capacity and skill initiatives. The food processing industry is expected to provide a major chunk of employment opportunities in the coming decade.

Fee: 2500 /- (Now Flexipay EMIs option availabe*)... Enroll Now

Fee: 2000 /- (Now Flexipay EMIs option availabe*)... Enroll Now

Fee: 2500 /- (Now Flexipay EMIs option availabe*)... Enroll Now

Fee: 2500 /- (Now Flexipay EMIs option availabe*)... Enroll Now

Fee: 2500 /- (Now Flexipay EMIs option availabe*)... Enroll Now

Fee: 5000 /- (Now Flexipay EMIs option availabe*)... Enroll Now

Share in India's food market

Share in total employment

Share in India's exports

Cropping intensity